Welding and Metal Fabrication

Have you always wanted to work with metal? Are you fascinated by the almost limitless possibilities of metalworking? Then this is the vocational training for you!

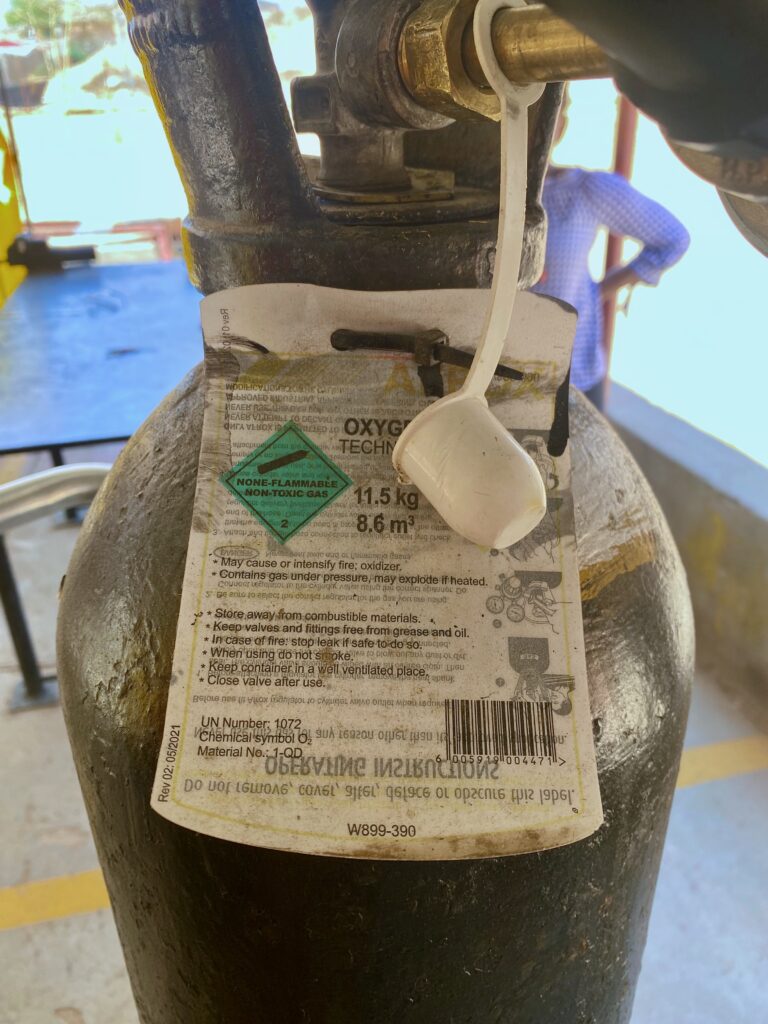

In this course, you will learn all the basics of metalworking. This ranges from working by hand with a hacksaw or file, to using various power tools such as angle grinders and drill presses, to using manual arc welding. You will also learn how to cut and weld steel with an oxy-acetylene torch. In addition to practical knowledge, you will also gain extensive theoretical knowledge, such as the application of safety-related work techniques and the properties of different metals. So if you enjoy working with metal and want to learn more about how to built up complex structures from it, such as domes, then this is the training you should apply for!

Facts about the course

- Duration: 6 months (two intakes per year, starting in January and July)

- NTA-level: 2

Content of the course

- Apply safety rules and regulations in a Metal Fabrication work environment.

- Plan and organize metal fabric work.

- Use hand tools for metal fabrication operation.

- Assemble and test Oxyacetylene welding equipment as part of metal fabrication.

- Weld mild steel using the manual Arc Welding process in the Down hand position.

- What are Welding and Fabrication?

- Basics of Electricity.

- Properties of materials.

- Workshop materials.

- Ferrous and non ferrous sections.

- Marking out.

- Joining sheet metal.

- Applied Mathematics.

Compulsory generic subjects

- Engineering Science

- English

- Entrepreneurship

- First Aid

- HIV

- Mathematics

- Occupational Health and Safety

- Technical Drawing

Perspectives after passing the course

- Applying at a company with the KAYEC certificate

- Opening your own business as an entrepreneur

- Participate in NTA-assessment if your KAYEC grades match the NTA-requirements

- Further studies of welding and metal fabrication (Level 3 etc.)

- Further studies in a related trade, such as Boilermaking